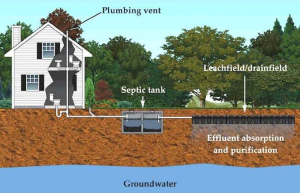

A septic tank is a buried, water-tight container. Oil and grease float to the top, while solid waste settles to the bottom in the form of sludge. Special compartments and an outlet prevent sludge and scum from leaving the tank and traveling to the drain field (also called the leach field).

Clogged or waterlogged absorption fields can damage the tank and pipes. Avoid putting paint thinner, polyurethane, anti-freeze, pesticides and other strong chemicals into the system. Click Here to learn more.

Wastewater from toilets, kitchen sinks and washing machines enters the septic tank through drains in your home. This wastewater contains fecal matter and other contaminants. Bacteria in the tank digest these solids. As the waste moves into and out of your septic tank, it separates into three layers. Oil and grease float to the top, waste particles fall to the bottom and sludge settles in the middle. The wastewater leaves the tank through a pipe that connects to your soil absorption system or leach field.

The leach field is an area of perforated, gravel- or rock-covered excavation in the ground. It works as a filter to remove harmful coliform bacteria, viruses and nutrients from the wastewater that passes through it. This process occurs naturally, with wastewater seeping into the soil and percolating through it. The drain field can be made up of trenches, beds, a mound or other porous surface.

A septic tank baffle wall, also called a partition wall or divider wall, keeps floating scum and other solids from clogging the inlet or outlet pipes. This reduces wastewater agitation and makes it easier for solids to sink to the bottom of the tank. It also allows liquid sewage to exit the septic tank into the leach field.

In some septic systems, a pump agitates the sludge to speed up its decomposition and to help it flow out into the drainage field. This can save on maintenance costs and extend the life of your septic tank and drainage field.

Another method of septic system treatment involves using a septic system with two tanks. The first tank — also called the anaerobic tank — is used to preprocess wastewater and prevent the solids from mixing with the incoming sewage. This can avoid the costly and unsanitary process of septic tank digestion.

Some septic tanks have tees at the inlet and outlet to allow more wastewater to pass through the tank at one time. This increases the hydraulic pressure and volume that a septic tank can handle and helps to ensure that all wastewater flows through the tank without clogging or flooding your drain field. If you have such a septic tank, you should limit the number of showers and laundry loads that you run at any given time to protect your drain field.

Treatment

As wastewater passes through a septic tank, solid materials settle to the bottom of the tank and form a sludge layer. Grease and other lightweight materials float to the top of the tank and form a scum layer. Between these layers is a liquid layer. When the septic system is working correctly, solids are separated from wastewater and do not make their way to the absorption field or clog pipes. A septic tank is a vital part of any sewage treatment system.

When a septic tank becomes full, it cannot remove all of the waste from the home in the same amount of time as it takes to fill the tank. This can cause the septic system to overflow into the drainfield, which is dangerous because sewage exposes people and animals to disease-causing organisms. The septic tank should be pumped regularly to avoid overflowing and contaminating the environment.

During the process of treating wastewater, bacteria in the septic tank generate gases, including hydrogen sulfide, which smells like rotten eggs. The gases are released through a vent pipe in the septic tank’s lid. The vent is a mushroom-shaped design that can be fitted with a charcoal filter to reduce odors.

After the septic tank is emptied, the wastewater enters the absorption field through a series of pipes in gravel-filled trenches. The wastewater is absorbed into the soil and grass above it. The septic tank-soil absorption system is the most common method of sewage treatment in rural areas. This treatment system has a high rate of success and is very efficient.

The septic tank and the soil absorption field both protect the environment by removing the majority of solids from the wastewater. This prevents the septic tank and drain field from becoming clogged or failing early, and it also prevents the wastewater from polluting groundwater or surface water. In addition, septic tanks can be conveyed to constructed wetlands for secondary treatment to further improve the quality of wastewater before being returned to the environment.

Disposal

All the drains in your home converge into a single pipe that leads to the septic tank, which is typically buried outside. Once it reaches the tank, the wastewater begins to separate. Oils and other fats float to the top and form a layer of scum, while the heavier solid waste sinks to the bottom, forming a sludge layer. The comparatively clear liquid middle is known as effluent. Bacteria inside the septic tank works to break down most of these solids, but not everything.

The septic tank is designed to hold the wastewater for enough time to allow settling and decomposition to take place. This helps reduce the volume of the sludge layer, and also allows for more efficient treatment. During this stage, the septic tank relies mostly on natural bacteria and sludge removal processes without any chemical additives.

Once the septic tank has been emptied, the sludge is conveyed to a secondary wastewater treatment. In most cases, this is constructed wetlands, but in some areas, it is sent to a centralized treatment facility. This process removes even more of the sludge, which is a major benefit because it prevents septic tank overflow and clogs in the drain field.

Since the septic system is so effective at removing solids, it is important to avoid flushing non-biodegradable waste items. This includes cigarette butts, cotton swabs and menstrual hygiene products. This type of non-biodegradable waste can clog septic systems and toilets, as well as pollute the environment.

A septic system needs proper maintenance to operate efficiently. Homeowners can help by limiting garbage disposal use and not grinding up glass, metal or other materials. They should also limit the amount of chemicals and disinfectants that they use, as these can affect bacterial levels and prevent the wastewater from being properly broken down.

Lastly, the septic tank must be pumped on a regular basis. When the time comes to pump, a truck will arrive to suck out all of the sludge that has built up over the years. The truck will transport it to a local sewage treatment plant, where it is combined with sewage from city sewer lines and treated. If the septic tank is not pumped regularly, the sludge layer can build up and overflow into the drain field, causing sewage to back up in toilets and other household appliances.

Maintenance

Your septic system treats waste water, but it can only do so effectively if it is well maintained. Improper maintenance of a septic tank can result in the contamination of groundwater, which can be a health risk for people using the home’s plumbing and can have ill effects on local flora, fauna, and bodies of water such as lakes and streams.

Septic systems must be inspected and pumped on a regular basis. The best way to know when it’s time for a pumping is to have your septic tank inspected and the sludge and scum levels recorded. If the sludge level is within six inches of the bottom of the tank or the scum layer is within 12 inches of the outlet, it’s time to call for a pump.

Having the tank pumped regularly ensures that the sludge and scum are removed before they can enter your drainfield, which protects the surrounding soil and prevents contaminants from entering public water supplies. Pumping is also a good time to inspect the system, make repairs, and keep records of the condition of the septic tank.

To help extend the life of your septic system, limit the number of household chemicals and wastes that enter the system. Avoid flushing anything other than toilet paper, human waste and sewage, such as cooking oil, non-flushable wipes (even the ‘flushable’ kind), cat litter, coffee grounds, tampons or condoms, paints and thinners, medicines and other household hazardous materials.

Talk to your septic professional about installing water conserving fixtures like low-flow shower heads and toilets, and front-load washing machines. It’s also a good idea to spread out the times when you wash and bathe. Doing everything at once means your septic system may be overwhelmed and can’t treat the wastewater adequately.

Finally, don’t plant trees or other deep-rooted plants over the septic tank or absorption field. These roots can grow into pipes and clog them. And never park or drive a vehicle or heavy equipment over the septic tank or drainfield. It’s important to maintain a clear path of access for future inspections and repairs.